In the world of industrial finishing and material protection, copper plating has established itself as one of the most versatile and valuable processes. By applying a thin layer of copper to the surface of metals and other materials, manufacturers gain access to a wide range of benefits, from corrosion resistance to improved conductivity. This guide explores the process of copper plating, its advantages, and the industries where it plays a critical role.

What is Copper Plating?

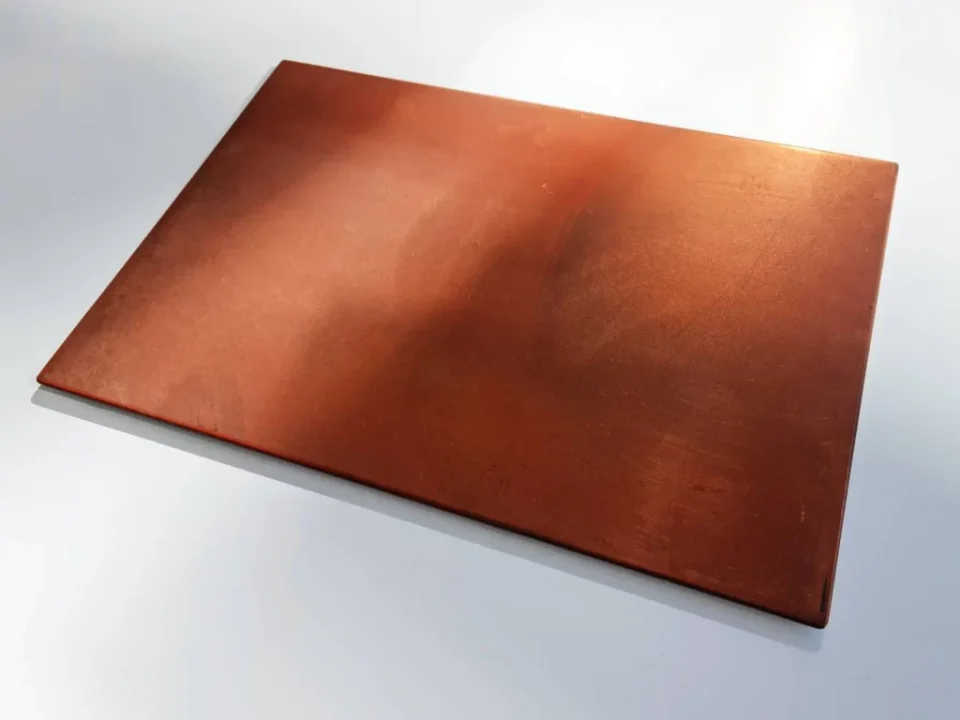

Copper plating is the process of depositing a layer of copper onto a base material. This is usually achieved through electroplating, where an electrical current is used to bond copper ions onto the surface of the object. The result is a smooth, durable finish that enhances both the performance and the appearance of the substrate.

The Process of Copper Plating

The copper plating process typically involves several key steps:

Surface preparation – The base material must be thoroughly cleaned and degreased to ensure strong adhesion.

Electrolyte bath – The component is submerged in a solution containing copper salts and other chemicals.

Electroplating – An electric current causes copper ions in the bath to bond with the material’s surface.

Post-treatment – The finished component may be polished or treated further to achieve the desired appearance and durability.

Each step is crucial in achieving a consistent and high-quality copper coating.

Benefits of Copper Plating

Copper plating offers a wide range of advantages across multiple industries:

• Corrosion protection – The copper layer acts as a barrier against moisture, oxygen, and chemical exposure.

• Improved conductivity – Copper is one of the best conductors of electricity and heat, making it ideal for electronics and electrical components.

• Enhanced durability – Components last longer due to reduced wear and surface damage.

• Cost-effectiveness – Extending the lifespan of materials reduces replacement and maintenance costs.

• Versatile finish – Copper plating can be applied to steel, aluminum, and other metals, as well as for decorative purposes.

Industrial Applications of Copper Plating

Copper plating is used across a wide variety of industries because of its unique combination of protective and functional qualities:

• Electronics – Essential for connectors, printed circuit boards, and other components requiring high conductivity.

• Automotive and aerospace – Protects engine parts, gears, and other components exposed to extreme conditions.

• Construction and infrastructure – Reinforces steel beams, pipes, and fittings with added protection against corrosion.

• Marine applications – Provides durability and resistance to seawater exposure.

• Medical equipment – Used for sanitary equipment due to copper’s natural antimicrobial properties.

Copper Plating vs. Other Finishes

Compared to painting or galvanization, copper plating provides longer-lasting protection and enhanced conductivity. While paint may peel and zinc coatings may lack strong conductivity, copper plating delivers both durability and performance benefits, making it the superior choice in many critical applications.

Sustainability and Long-Term Value

Copper is fully recyclable, and its use in plating helps reduce material waste by extending the life cycle of components. This not only supports sustainability goals but also delivers significant cost savings over time.

From its role in electronics to heavy industry and beyond, copper plating continues to be one of the most effective and versatile finishing methods available today. By combining durability, conductivity, and cost-efficiency, it ensures that components are built to last and perform at the highest standard.